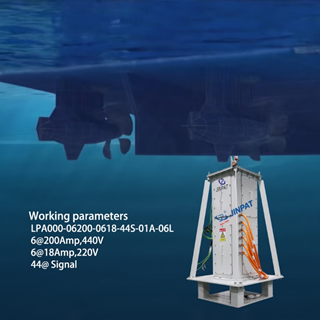

Ship Podded Propeller Slip Rings by JINPAT Electronics

Automation Equipment2023-04-13

Electrical slip ring solely is enough to satisfy heavy machines and machine tools. An integrated slip ring is needed to enable transmission of fluid like coolants and lubricants. Similarly, in some automated production machines, an integrated rotary union is demanded to transmit compressed air. JINPAT Electronics has provided numerous versatile slip rings for application that requirement transmission of power, signals, fluid and gas. One of the high-end mechanism as the above mentioned applications, is the ship podded propeller.

Generally speaking, ships that adopt podded propulsion tend to be of large volume. Slip ring allows the propulsion system to rotate in a specific angle while providing a constant drive and signal transmission. This unique propulsion system not also provide drive to the ship but also works as a rudder to steer the direction. To cater the size of the ship, a matching slip ring is demanded to support high power large current transmission and to endure high working voltage. Among JINPAT’s slip rings for ship podded propulsion systems, most are hydraulic pneumatic integrated slip rings.

LPA000-06200-0618-44S-01A-05L is a 200Kw hydraulic pneumatic electrical slip ring. In its power unit, there are 6 200A high power capacity channels. 6 18A power channels an 44 signal channels are integrated within the integrated through bore slip ring, which is the weak power unit. This slip ring is optional at IP65 and IP44. JINPAT Electronics has made a breakthrough in solving to enable high power capacity in a relatively compact figure.

For ships of larger scales, JINPAT Electronics provides custom integrated slip ring at 1MW, 3MW and 7.5MW. LPA000-034000-01PE-0606-72S-11L-01A and LPA000-062000-0606-01PE-72S-11L-01A are two JINPAT integrated slip ring models. With more channel numbers, these custom slip rings are able to support coolant channels and provide a more robust drive to the propeller.

Facebook

Facebook

Reddit

Reddit

Twitter

Twitter

LinkedIn

LinkedIn

Youtube

Youtube